Optimize Performance With Durable Undercarriage Components

In the world of hefty equipment and devices, the role of undercarriage parts is extremely important in ensuring optimum performance and longevity. The efficiency and effectiveness of these parts can significantly influence the total operation of equipment, making the selection of durable undercarriage components an essential decision for managers and operators alike. By discovering the intricate relationship in between sturdiness and performance in undercarriage parts, a much deeper understanding of the subject emerges, losing light on the critical elements that drive operational success. As we browse with the complexities of undercarriage component, upkeep, and longevity option, a comprehensive expedition awaits to introduce the key techniques for accomplishing peak performance in sturdy applications.

Benefits of Utilizing Resilient Undercarriage Parts

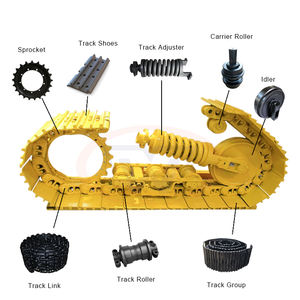

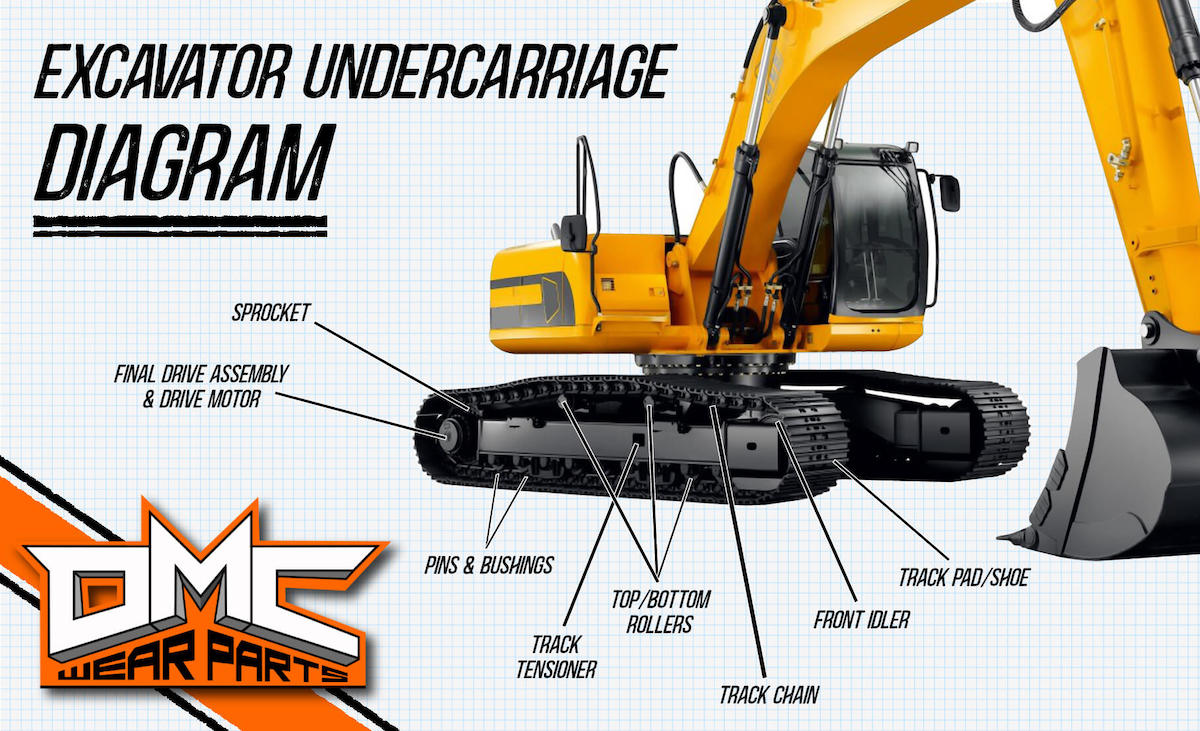

Utilizing sturdy undercarriage parts not only boosts the durability of hefty equipment yet additionally minimizes maintenance prices considerably. By purchasing premium undercarriage elements, such as tracks, sprockets, idlers, and rollers, tools operators can experience enhanced uptime and boosted total efficiency.

In addition, the long life of hefty equipment is straight linked to the quality of its undercarriage parts. Long lasting parts can endure the roughness of requiring applications, making sure that the tools continues to be functional for extensive periods. As an outcome, operators can avoid costly downtime and maintenance costs, inevitably taking full advantage of the return on investment for their machinery.

Elements Impacting Undercarriage Durability

The toughness of undercarriage parts in hefty machinery is influenced by various vital aspects that directly effect efficiency and long life. High-quality materials, such as solidified steel, are necessary for withstanding the extreme conditions and heavy loads that undercarriage parts are subjected to - undercarriage parts.

Furthermore, ecological elements can have a substantial influence on the durability of undercarriage components. Direct exposure to unpleasant materials, extreme temperature levels, and severe working problems can increase deterioration on undercarriage components. Therefore, selecting undercarriage components that are particularly created to withstand these environmental difficulties is crucial for making certain resilience.

Additionally, the layout and engineering of undercarriage parts have a straight impact on their longevity. Parts that are designed to distribute tons evenly, reduce friction, and reduce tension concentrations are more probable to have a much longer life expectancy - undercarriage parts. By considering these vital factors, equipment operators can make the most of the toughness and efficiency of their undercarriage elements

Upkeep Tips for Lengthening Undercarriage Life

Carrying out routine maintenance regimens is vital for expanding the life-span of undercarriage components in hefty machinery. To extend the undercarriage life, it is vital to regularly inspect for wear and tear. On a regular basis inspect for absent or loosened screws, damaged rollers, or misaligned tracks, as these problems can rise and trigger more damage if not dealt with promptly. In addition, make sure that the undercarriage is properly lubricated according to manufacturer standards to reduce friction and avoid early wear.

Another important maintenance tip is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can speed up wear and deterioration, bring about pricey repair work. Cleaning the undercarriage after operation in rough conditions is suggested to prevent these issues.

Lastly, monitoring and recording maintenance tasks can help in creating an aggressive maintenance routine. Maintaining detailed records of repair work, evaluations, and replacements can give valuable understandings right into the undercarriage's problem and efficiency gradually, assisting in predicting and protecting against prospective failures. By following these upkeep tips diligently, drivers can significantly boost the longevity and efficiency of undercarriage components in hefty equipment.

Choosing the Right Undercarriage Components

Picking proper undercarriage parts is important for making the most of the performance and long life of hefty equipment. There are several aspects to take into consideration when it comes to selecting the right undercarriage parts. One crucial variable is comprehending the certain needs of the maker and the setting in which it will operate. Different applications might ask for various kinds of undercarriage parts, such as tracks, sprockets, rollers, and idlers. It is vital to select parts that are designed to withstand the specific problems the device will certainly experience, whether it be rough surface, rough products, or extreme temperature levels.

Deciding for credible brands known for generating high-performance and sturdy undercarriage components can substantially influence the general effectiveness and longevity of the equipment. By thoroughly choosing the appropriate undercarriage elements, devices owners can improve efficiency, lower downtime, and expand the life-span of their hefty equipment.

Study: Boosted Performance With Sturdy Parts

Integrating long lasting undercarriage components has actually demonstrated significant enhancements in machinery efficiency. One situation research study involved a construction business that upgraded its excavator's undercarriage elements to extra durable options. The firm observed a noteworthy decrease in downtime because of undercarriage maintenance, causing boosted productivity and expense savings. The sturdy components stood up to extreme working conditions, lowering wear and tear considerably.

In another circumstances, a mining procedure changed the undercarriage components of its excavator with high-grade, long why not look here lasting options. Read Full Report This button resulted in an exceptional enhancement in the bulldozer's maneuverability and overall performance. The equipment could browse difficult surfaces extra successfully, leading to improved operational efficiency and decreased gas intake.

Additionally, a logging company purchased resilient undercarriage components for its forestry tools. The updated elements exhibited extended life-span and enhanced resistance to abrasion from rough terrain. As a result, the firm experienced reduced maintenance costs and enhanced devices uptime, inevitably boosting its profits. These study highlight the concrete benefits of making use of sturdy undercarriage components in maximizing equipment performance and longevity.

Verdict

Finally, using durable undercarriage components can considerably improve efficiency and durability of heavy equipment. Elements such as correct maintenance and picking the best parts play an important function in making the most of undercarriage sturdiness. By executing these strategies, organizations can decrease downtime, rise performance, and eventually reduce functional costs. Situation studies have actually shown that purchasing long lasting undercarriage components can result in improved total performance and efficiency in different markets.

The performance and performance of these components can considerably affect the total procedure of machinery, making the selection of long lasting undercarriage components an official source important decision for managers and operators alike.Integrating long lasting undercarriage components has actually shown considerable improvements in equipment efficiency. These instance studies underscore the tangible benefits of using resilient undercarriage parts in enhancing machinery efficiency and long life.

In verdict, making use of durable undercarriage components can significantly improve performance and longevity of hefty equipment (undercarriage parts). Instance researches have actually revealed that investing in resilient undercarriage parts can lead to improved total efficiency and performance in numerous sectors

Comments on “Stay Ahead of Wear and Tear: Important Maintenance Tips for Undercarriage Parts”